What does a quality control flag mean?#

%%HTML

<center>

<iframe width="560" height="315" src="https://drive.google.com/file/d/1iX3-8SGGAB95zyDQqxT9bVtH7ediBJJE/preview" width="640" height="480" title="The Argo Data" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

</center>

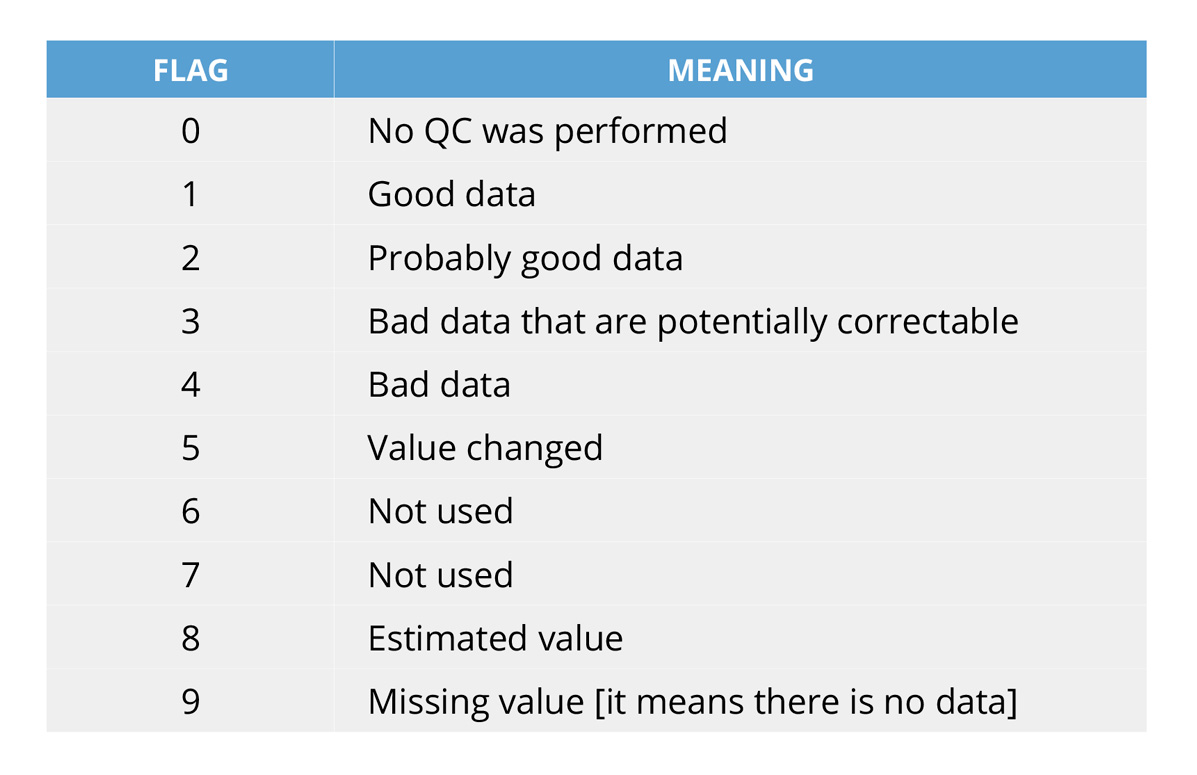

Each data will have a specific quality flag assigned that indicates its status! Both Real-Time quality control and Delayed - Mode quality control follow a solid quality flag policy. Here are some examples that show how robust this quality flag policy is:

• The value assigned by a test cannot override a higher value from a previous test. Taking the Real-Time quality control as an example: a QC flag ‘4’ (bad data) set by Test 11 (gradient test) cannot be decreased to QC flag ‘3’ (bad data that is potentially correctable) set by Test 15 (gray list).

• A measurement with QC flag '4' (bad data) or '3' (bad data that are potentially correctable) cannot get a better QC flag in other quality control tests.

• Since salinity (PSAL) is almost always calculated from temperature (TEMP) and conductivity (CNDC), if the temperature is flagged '4' (or '3'), then salinity is also flagged as '4' (or '3').